Keigo Nakamura

It’s autumn on calendar, greenhouse is warmed up and gradually sound of end of year is coming step by step. I hope you are doing fine with good health.

From October 28 to November 4, I and my staffs in charge of import and quality together visited Holland, and checked bulbs and situations there, here I report.

① Climate in Holland and bulbs in 2012

Roughly speaking, climate of this year was…

Temperature:Lower (normal in statistic). Only 2days in August reached over 30 degrees.

Lower than hot 2011.

Sun light:Sun (total in hours) from Apr to Oct was…

Normal 1175h

2010 1389h

2011 1317h

2012 1177h

Normal sun hour, but can be said less than recent years.

Rain :Total amount of rain was normal, but small amount of rain has continued to spread. middle of August and beginning of September was only days without rain more than 1 week after April. Growers almost needn’t irrigate.

Bulb enlargement:LA is little better. Oriental/OT is average as expected.

(Much less than crop 2011, which is extremely good crop.)

Maybe because of more rain, Roots looks little thinner and longer

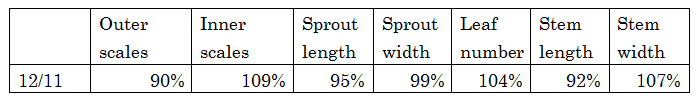

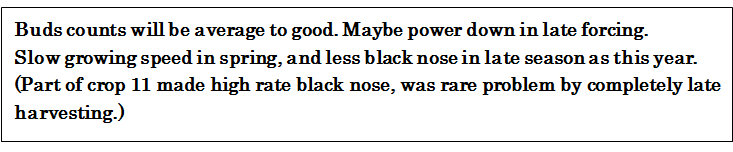

Hereunder is Sprout development checking result, comparing to crop 2011.

The impression by sprout checking this year was “low sprout, but not thin”.

Picture is sprout of Nova Zembla in South Holland, which is average image of general. Less neck ditch and seems widest point of sprout stays lower.

Minus 5-10 degree frosts happened in Oct 26-28, soil temperature is already low and further sprout development stopped.

Mild climate and sprout development like mentioned in first page, doesn’t fit each other. So it’s difficult to judge the power of bulbs of Orientals though.

② Harvesting situation and schedule

We sometimes reported you about harvesting is getting later with global warming etc, longer transportation by eco schedule of shipment influence the late arrival time of new crop to Japan. We feel the change specially in this year.

Delay of harvesting LA is serious situation.

It’s time normally many bulbs arrive in exporter’s warehouse and waiting quality check. This year, we could see only few variety at every exporters, and some exporter said arriving amount compare to last year is about half.

Reasons of delay of LA would be…

1. Disinfection against botrytis was stronger during summer with more rain, made dying of plant later.

2.Harvest can’t start, due to slow sales.(If it’s not sold, maybe destroy)

3.More grower became specialist of LA, So harvesting period spread from end of October to December.

(In past, many Oriental growers also produced LA, and had to finish harvesting before Oriental.)

※Harvesting of Oriental starts since now. Dying stage in field looks normal, recently temperature is going down, so delay might be recovered.

Total delay is half month, due to shipping takes 1 week longer and harvesting of LA delay 1 week to 10 days.

It takes more than 2 months between grower’s grading and our delivery to customers. That means most variety which neither harvested, nor arrived at exporter, won’t be delivered you within this year.

We are doing best effort to receive earlier though,

LA will be first half of January (late harvest variety will be even later)

Oriental Turbo will be Middle or end of January.

Oriental/OT might be early February we can deliver.

Those are schedule of earlier variety. Please understand planting in end of Dec to January should be managed with old crop (LA/ Asiatic) or SH bulbs, and also count for planning next years.

③ System of bulb production is also changing

Nowadays, most bulbs are produced in east and south Holland, so local contract grower became more important.

For the higher quality management, partnership to contract grower is not only “1 to many” as before, but also “1 to 1”, is remarkable.

Characteristic of both parties which I saw was…

“1 to many owner” type

Popular good contract grower has big facility, and had invested in time for equipment like new machine, warehouse, advanced equipment etc. (picture is triple aqua grader. Rough grading is already done at washing.)

Contract grower of 1 to many type deals many lot from various growers. The sense to manage the virus lot (specially PlamV) is higher, and also quality data of each lots are communicated with owner growers openly, which give pressure to stop decrease the quality standard.

“1 to 1 owner” type

Owner grower’s growing technique and quality mind for each lot is important, also has bigger influence to decision and capital.

In this case, contract grower has own main job sometimes, and facility level is quite depends. Because relation between owner and contractor is strong, there is a possibility to do grading at field area, which to lower the cost in the future. Contract grower doesn’t have the other owner grower, so virus control is simple and easy.

④ Approach to plam-virus matter

Eliza test is widely used now, many growers took the test by leaf sample from field in September.

Exporters also got most results, and that mean virus lot is difficult to sell.

Influence of commercial selection is far big, so growers we visited this time also started following concrete method.

・No disinfection for bulbs. Spread by disinfection is concerned. Really?

(Rotten problem of NL crop 2011 was concluded that harvesting was too early in warm soil temperature in beginning of November. This year, deep frost happened already several times, both soil and air temperature is low like end of November. Also exporter must disinfect as usual.

・No recycle water at washing machine. Or only end part of machine is done by fresh water. Because of same concern as disinfection.

・Infected lot will be harvested at end.

・To wash and disinfect the machine after process of infected lot.(Normally it’s been done at the end of season.)

・Virus check for mother bulb and planting material is checked by scale Eliza test.

Disinfection spraying machine Independent disinfection by Bins.

Both don’t recycle disinfection and no touch between lots (or bulbs).

It looks quite nervous job though, some exporter also do similarly. Whole Holland started the act to eliminate virus and spreading.

The growers who reacted the matter in time, already thrown away infected planting stock before planting of NL 2012. (which was cost over 100000 euro.)

Most growers will also destroy the infected lot since crop 2013 according to result of Eliza test.

Our company basically don’t deal variety or lot, which exporter informed us higher virus contents, so already decided not to deal variety such as Striker, Caruso, Talisker, Garanza, Ice Bear, etc.

We apology customers may concerned about it.

Bulbs are grown at outside, so we can’t say virus becomes zero as well, but way of thinking like “to hope no symptom in some climate” is rather risky. That may lower the value or popularity at flower shop or end user, also may lose reputation as forcer.

Also I recommend you understand % of test result just as a reference.

(Now, exporter and research institute together study the correct way of sampling or accuracy of result, by experiment.)

Hope your understanding to the Dutch suffering improvement in good way.

⑤ Our test greenhouse becomes good to see.

After mid-summer test, late forcing of NL crop and SH is in growth. Together with LA flowering, we hold Autumn bulb planting bazaar on November 10th, which is open for everybody. (Tulip bulb is also on sale.)

Your visit in the other days is also welcome, please contact us. We are looking forward to see you in here.